Sai Gon - Vinh Long Beer Joint Stock Company (SAVIBECO) is proud to be one of the members of

Saigon Beer - Alcohol - Beverage Corporation (SABECO).

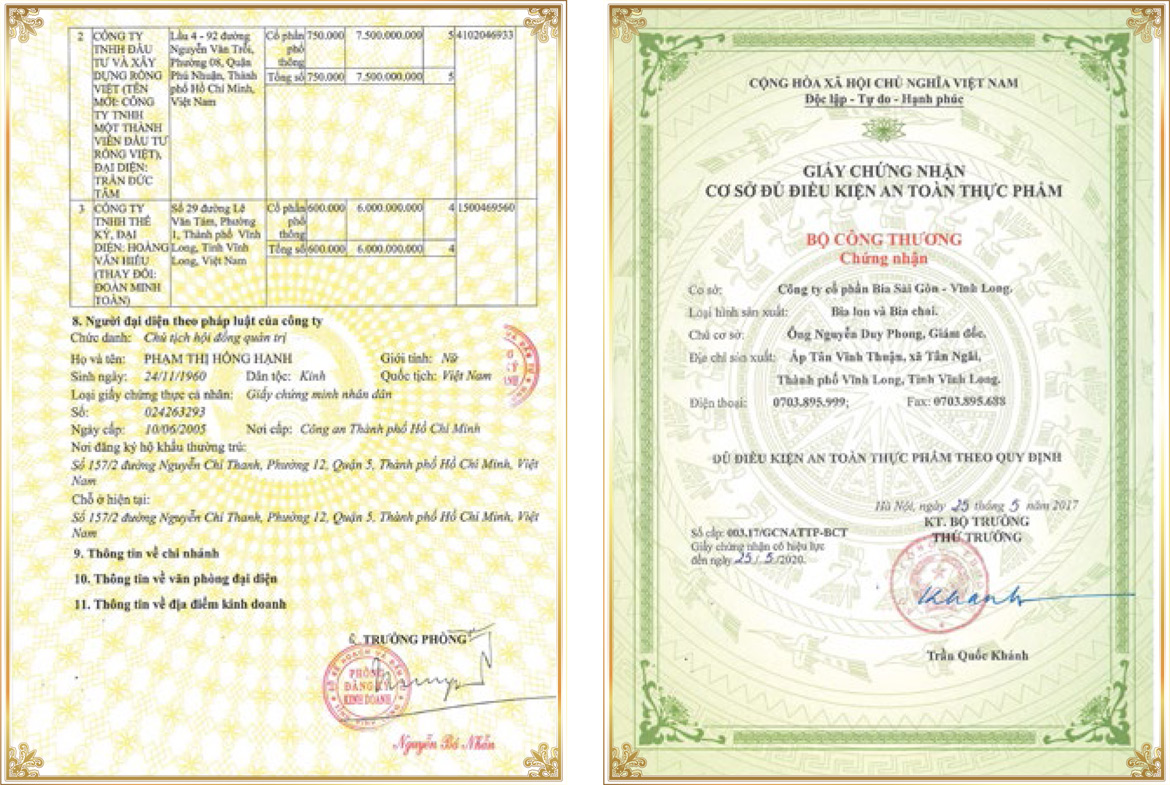

Transaction name:

SAI GON – VINH LONG BEER JOINT STOCK COMPANY

Address: Tan Vinh Thuan Hamlet, Tan Ngai Commune, Vinh Long City, Vinh Long Province

Tel: +84 02703 895 999 +84 02703 895 688

Fax: 02703 895 688

Website: www.savibeco.com.vn Email: [email protected]

Legal Representative: Ms. PHAM THI HONG HANH

Position: Chairwoman of the Board

CEO: Mr. NGUYEN DUY PHONG

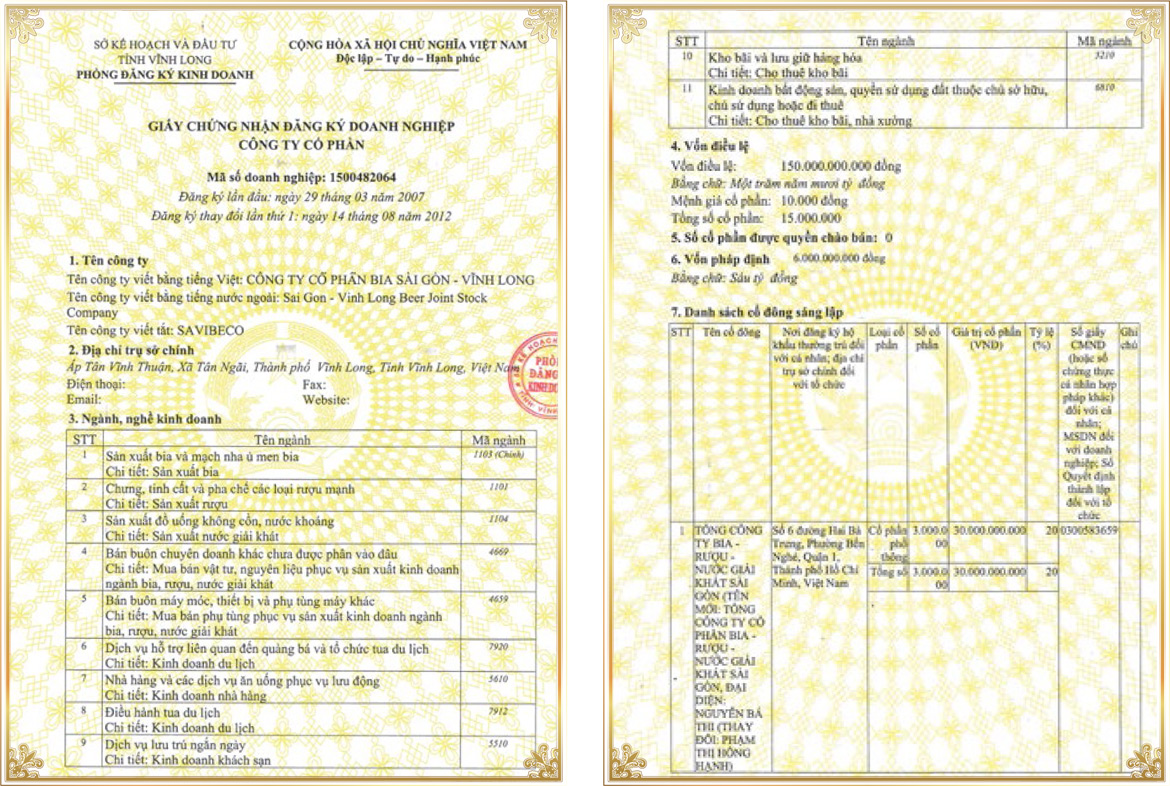

Sai Gon - Vinh Long Beer Joint Stock Company was established in accordance with Decision No.10/2012/QĐ-SAVIBECO-HĐQT dated August 9, 2012 by the Chairman of the Board.

Business Registration Certificate No: 1500482064 by Vinh Long Department of Planning and Investment, dated March 29, 2007; 1st amendment on August 14, 2012.

Charter capital: 150,000,000,000 VND.

Main business lines:

- Production of beer, alcohol and beverage.

- Trading in material and accessories for production. and trading of beer, alcohol and beverage.

- Trading in restaurants, hotels, tourism and travel-related services.

Investment scale:

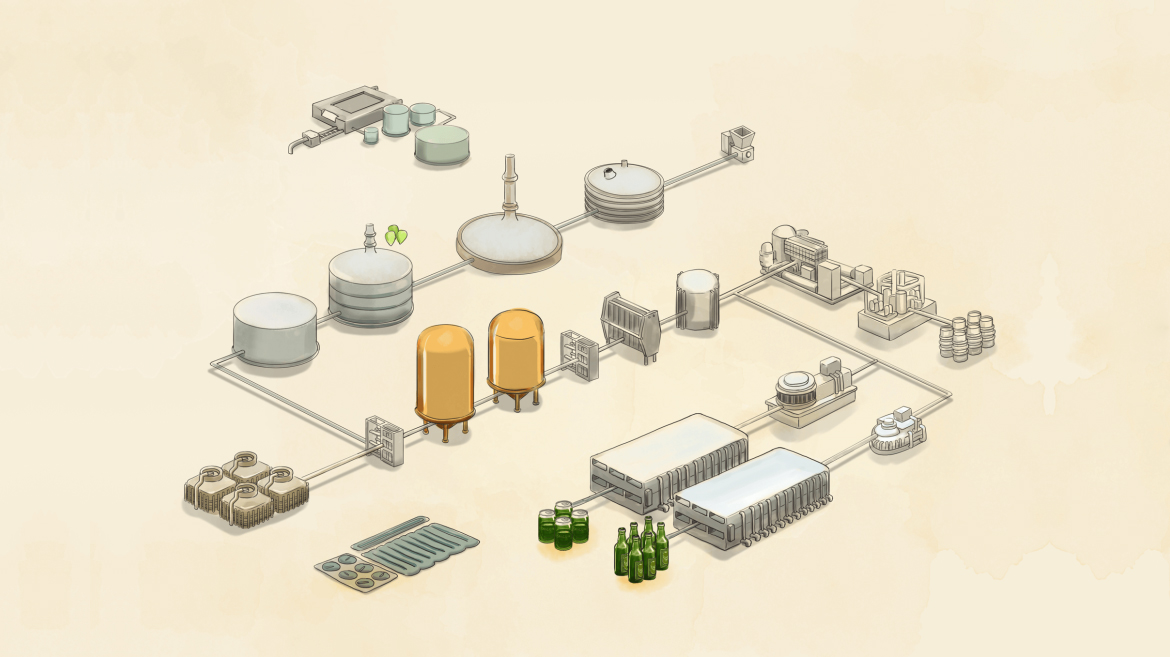

The total land area allocated by Vinh Long People's Committee is 44 hectares, of which the Brewery construction area is 12.26 hectares. SAVIBECO is planning to cooperate with foreign partners to scale up its brewery, utilize allocated land area and increase annual beer production capacity to meet the increasing demand of customers.